Computer Chronicles Revisited 111 — Felix, Key Tronic KB5153, L-PC Lite-Pen, MicroSpeed FastTrap, Manager Mouse, and NestorWriter

Gregg Williams, writing about the introduction of the Apple Lisa for the February 1983 issue of Byte Magazine, noted that when it came to a choice of an input device to use with the new computer’s graphical interface, the designers “passed over such devices as light pens and touch-sensitive video panels in favor of the mouse, a pointing device used in several Xerox PARC machines.”

Apple’s main refinement–not necessarily an improvement–to the PARC mouse design was only providing a single button. According to Williams, “Apple broke with the conventional wisdom of two- and three-button mice after user tests indicated the people aren’t always sure which button to push on a multi-button mouse.”

While it’s true that the legacy of Steve Jobs-directed product design was to assume your customers were all two-year-olds, in practice there were many users of the Macintosh–the more successful follow-up to the failed Lisa–who sought greater functionality than a one-button mouse could provide. And by the spring of 1988, when this next Computer Chronicles episode on input devices first aired, there were now also millions of users on the IBM PC platform interested in mice, as well as light pens, trackballs, and other alternatives, to get more done with their machines.

Stewart Cheifet opened this episode by asking Gary Kildall if there was any one type of computer input device that was better than the others. Kildall said that general purpose computers had long relied on a general purpose input device–the keyboard–as a standard that anybody could use. But now we were seeing more and more specialization, such as a computer that could run a kiosk to buy shoes using a touch panel. So as we continued to see more specialization in computers, we would also see more specialization with their input devices.

Postal Service Runs on Bar Codes

Wendy Woods presented her first remote segment, narrating B-roll footage of the main facility of the United States Postal Service’s San Francisco division. Woods said that most people probably didn’t think about what happened to a letter once it’s been posted, except to hope that it arrived at its destination. At the San Francisco division, that letter would join about 8.5 million others posted the same day.

Faced with about 162 billion envelopes and boxes mailed each year, Woods said the Postal Service was eager to expand its automated mail sorting system. Tony Mendicino, the San Francisco division’s acting director, told Woods that the volume was getting so large, if the Postal Service had done nothing to modernize its facilities, it would have run out of space for manual cases to process the mail.

Woods said the newest computerized input tools of the Postal Service’s system were optical character readers and bar code sorters. Working in tandem, they read the last line and ZIP code of an address and transformed that information into binary bar code data, which was sprayed onto the envelope to expedite sorting. The equipment could process close to 30,000 pieces of mail per hour, which was about 50 times faster than hand sorting–and about one-tenth of the cost.

Mendicino noted there were discounts available to major mailers who presorted their mail and complied with readability procedures, such as preprinting the bar code. That provided the most efficient means for the Postal Service to use its automated system.

Who Needs a Mouse When You Have a Pen?

Dan Mertens and Victor Kley joined Cheifet and Kildall in the studio for the next segment. Mertens was the corporate marketing manager with Washington-based Key Tronic Corporation. Kley was chairman of California-based Lightgate.

Kildall said the mouse was popularized by the Macintosh and now seen as a standard input device. He noted that both Mertens and Kley’s companies had products that effectively redesigned the mouse. So what were the shortcomings of the traditional mouse?

Mertens said the mouse required a free area on the user’s desktop to operate. Additionally, the user normally performed some sort of operation on the keyboard first before reaching for the mouse, which led to a lot of lost time. So if you could bring that all into one package, it made for a more efficient input process.

Kley agreed that the mouse took up a lot of space on the desk. He added that there was no relationship between the mouse and the screen. The mouse also had serious maintenance problems, such as having to clean the lint out of the part with the ball.

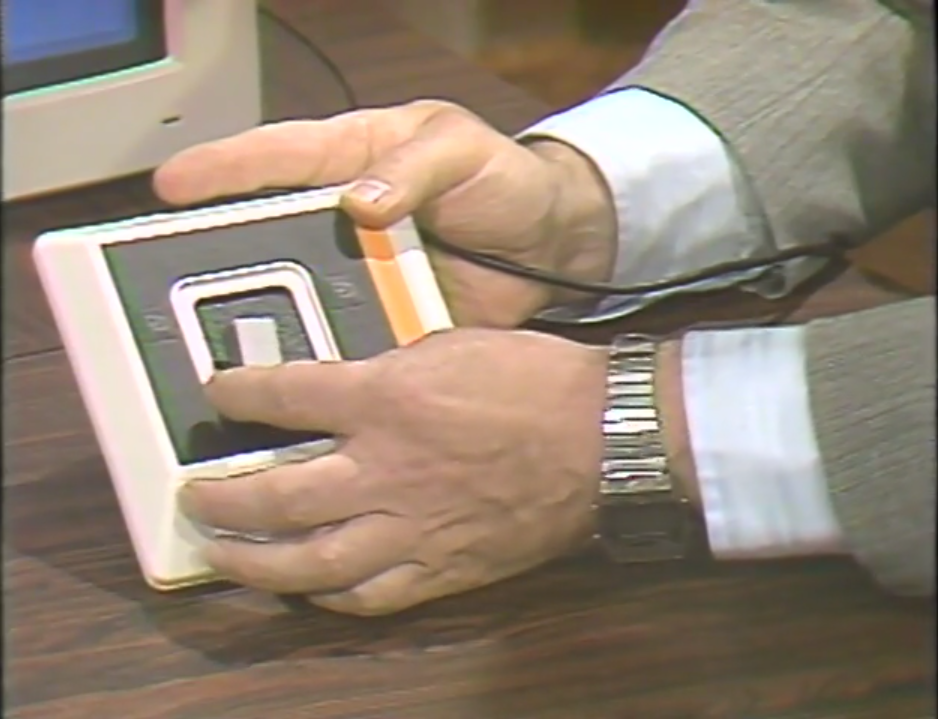

This led Kley into the demonstration of his company’s input device, Felix, which was a “mini-mouse,” or rather a miniature optical-data tablet (see below). There was a one-for-one relationship between the motion of Felix and the screen. Felix used the index finger, thumb, and forefinger–the same muscle set that a person used to draw or write–rather than the wrist and upper arm.

Kley said you held the Felix control the same way you would a pencil. He demonstrated this by using Felix to move a cursor in a drawing program running on a Macintosh II. Kley explained that when the user moved Felix to a corner and clicked, the cursor would automatically move to the corresponding corner of the active window on screen. This meant the user didn’t need to accurately position the cursor as with a mouse. Instead, the user could “feel” the corner with their hand.

Cheifet asked how much Felix cost. Kley said the product was available for the Macintosh II and Macintosh SE for $149.

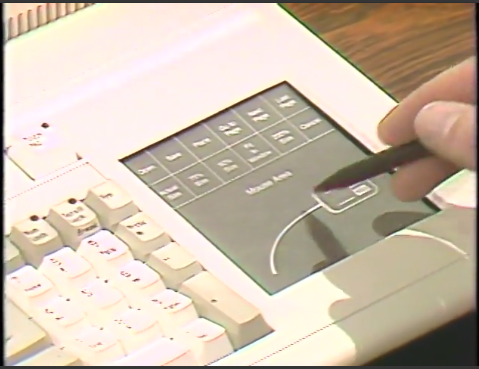

Moving to the IBM side of things, Cheifet and Kildall joined Mertens on the other side of the studio, which had an IBM PS/2 set up with Key Tronic’s KB5153 Touch Pad Keyboard and running Aldus’ PageMaker on Microsoft Windows. Unlike a modern laptop touchpad, the Key Tronic touchpad was designed to be used with a stylus (see below), and an overlay, which divided the touchpad into a “mouse area” and a set of controls tailored to the specific application running. For this demo, Mertens showed how you could select and resize a text box in PageMaker. The overlay included a number of specific commands the user could select with the stylus, such as opening or saving a file.

Mertens then exited PageMaker and loaded Lotus 1-2-3 on MS-DOS. He changed the overlay on the touchpad to one specifically designed for 1-2-3. Mertens noted that 1-2-3 was not designed to work with a traditional mouse. The overlay therefore did not include a mouse area, but was instead divided into a grid, with each square representing a specific 1-2-3 command or macro. For example, Mertens touched one square, which automatically brought up a graph created from the loaded spreadsheet.

Mertens then switched back to the spreadsheet and used the touchpad as a “fast cursor” to move through the rows and columns. And as the touchpad was touch-sensitive, you didn’t even need to use the stylus for this function. You could just use your finger.

Cheifet asked how much the Key Tronic keyboard cost. Mertens said $249 was the suggested retail price.

F**k Everything, We’re Doing Three Buttons and a Wheel

A trio of guests–Billy Lewis, Tim Barry, and Charlie Kennedy–joined Cheifet and Kildall at the desk for the next segment. Lewis was president of The Lite-Pen Company. Barry was president of MicroSpeed, Inc. Kennedy was a product manager with Pennsylvania-based Numonics Corporation

Kildall opened by noting that light pens had been around as an input device for the IBM PC since its debut in 1981, although he hadn’t seen them used much. What kind of applications were light pens used for? Lewis, whose company made the L-PC Lite-Pen, said they were used in niche areas. For example, in hospitals doctors and nurse used light pens with software designed to track patient care. Cheifet asked what the advantage was of using a light pen over a keyboard in such a setting. Lewis said the hospital didn’t have to teach everyone how to use the keyboard or a specific program. The software was menu-driven, so as fast as the staff member could think, they could select an option with the light pen.

Lewis then demonstrated the L-PC Lite-Pen on a drawing program running on an IBM PC. He showed how you could draw directly on the screen or make a menu selection with the Lite-Pen. He said this made the Lite-Pen the most “natural” of computer input devices.

Kildall asked for an explanation of how the Lite-Pen actually worked. Lewis said the Lite-Pen detected the movement of the electron beam running across the cathode-ray tube monitor, which happened 60 times per second. At the point of contact, the display sent a pulse back to the computer, which then registered the coordinate information.

Turning to Barry, Cheifet asked why his company, MicroSpeed, offered a trackball instead of a mouse. Barry said users preferred the trackball due to the lack of space on their desks for a mouse. And since the trackball was stationary, a person could use it without looking down at their hand and having to reposition it before the mouse moved off the table.

Barry then demonstrated his company’s trackball, sold as the MicroSpeed FastTrap. This was a trackball that not only featured three buttons–take that, Mr. Jobs–but also included a separate trackwheel. To demonstrate, Barry used the FastTrap to navigate a spreadsheet. The trackwheel provided page up/page down functionality.

Cheifet asked what the three buttons did. Barry said for this template, the buttons were used to pull up a menu and select items. MicroSpeed said FastTrap came with several built-in templates for major business application programs, including Lotus 1-2-3, WordPerfect, and SuperCalc.

Cheifet asked how the FastTrap would be used in a 3D application such as computer-aided design (CAD). Barry said the trackwheel controlled the third axis, which could rotate an image or zoom in and out. It depended on how the CAD program’s interface was developed.

Finally, Cheifet asked about the price of the FastTrap. Barry said it retailed for $149.

Turning to the third guest at the table, Cheifet asked Kennedy about his company’s product, the Manager Mouse, which was a cordless mouse. Specifically, Cheifet wanted to know what was the benefit a cordless mouse. Kennedy said software that relied on windowing features, such as CAD and desktop publishing applications, typically supported a mouse. But a mouse cable generally limited the locations where it could be used. Going cordless provided the user with a larger work area, while still providing precise control.

Cheifet added, however, that the Manager Mouse still required the user to maintain a “line of sight” between the mouse and the computer. Kennedy said that was correct. The Manager Mouse relied on infrared light, so there needed to be a clear path from the mouse to the receiver. Cheifet asked about the range. Kenney said if the Manager Mouse was directly in front of the receiver, it would work at a distance of up to 4 feet. There was a 90-degree cone of reception, however, so at the 4-foot limit the width of the work area was only about 5 feet.

Cheifet said that aside from the infrared receiver, this was otherwise a regular mouse. Kennedy added that the Manager Mouse did not rely on a traditional roller ball as a tacking mechanism. Instead, a pair of wheels on the bottom of the device tracked the user’s movements. This eliminated the need for periodic cleaning and maintenance.

Kennedy then demonstrated the Manager Mouse with Dr. Halo III, which sadly was just a PC graphics editing program and not a Commodore 64 game where Master Chief destroys futuristic viruses using colorful medicine capsules. Kennedy used the Manager Mouse to create a simple picture of the Manager Mouse. Cheifet asked if the Manager Mouse used a 9-volt battery for power. Kennedy said no, there was a rechargeable nickel-cadmium battery. The back of the Manager Mouse’s receiver was fitted with a power jack, which could be used to recharge the mouse overnight. He added the battery has an estimated life of 10 hours between charges.

College Orientation on Video Disc

Wendy Woods returned for her second remote segment, this time reporting from De Anza College in Cupertino, California. Woods said that when new students arrived at the school this fall, part of the orientation process would take place at a computer running an interactive video disc. Students would learn the kind of courses available, how to plan out their program, and how to get around the campus.

Students used the video disc by touching the screen. College officials chose this touchscreen interface because it was easy to use. Don Perata, De Anza’s vice president of student services, told Woods that the touchscreen was the most critical component of the orientation program. When you considered the number of students enrolled at De Anza, and their varying degrees of sophistication when it came to using computers, Perata said they wanted to keep the interface simple, so they didn’t have to teach students how to use the program.

Woods said De Anza was pioneering the use of this technology to take the place of timely and repetitive sessions for student orientation. So far, the experiment seemed to be working well. So well that after recently completing a test run with several hundred students, De Anza now planned to use it with 1,000 incoming freshmen in the fall 1988 semester.

Even in 1988, Companies Used “Artificial Intelligence” to Peddle Their Wares

For the final segment, Michael Buffa joined Cheifet and Kildall back in the studio. Buffa was the president and chief operating officer of Rhode Island-based Nestor, Inc.

Kildall said that Nestor offered a program, NestorWriter, that claimed to recognize handwritten characters. Buffa said that was correct. Kildall followed up, asking why anyone would do that instead of just using a keyboard. Buffa said there were some applications where a user could not–or would not–use a keyboard, such as lenders underwriting mortgage applications. There was also many cases on Wall Street where brokers have been wanting to use an alternative to keyboard input.

Kildall clarified that NestorWriter was therefore not intended to be a consumer or end-user product. Buffa said that was right, Nestor had no plans to mass market the software. It was oriented towards specific niches.

Kildall asked if NestorWriter could recognize anyone’s handwriting or if there was a training process. Buffa said the unique thing about NestorWriter was that it was based on a neural network-artificial intelligence concept that closely emulated the way the human brain functioned. So anyone could train the system to recognize their unique way of handwriting. He added that NestorWriter worked with English, French, and Japanese Kanji character sets.

Cheifet asked how long the training process took. Buffa said it took between 30 minutes and an hour depending on your handwriting.

Buffa then conducted a demonstration of NestorWriter. He showed how you could enter data from a form into a computer. He placed a paper form on a large digitizing tablet, and then used a pen to navigate the user interface on the NestorWriter software. Buffa noted that the software could store handwriting profiles for a number of different users.

Continuing the demo, Buffa calibrated the paper form to the digitizing tablet. He then entered data by using the pen to write on the paper form. As Buffa entered the information, it was immediately stored in the computer’s database. He reiterated the form was on a standard digitizing tablet, which was made by a number of different manufacturers.

Buffa also demonstrated how you could easily make corrections. He intentionally misspelled some words on his form. But he was able to go back, write over the previous letters, and the software made the corresponding changes on the screen. Kildall asked about the controls on the side panel of the digitizing tablet. Buffa said that if the system could not recognize a certain character–say because the user’s handwriting changed throughout the day–the side panel called up a training function to re-train the software.

Next, Buffa demonstrated what he called a prototype of a “paperless office” product that used an electronic display to show a data entry form. The form was overlaid on a screen that the user can write to directly. Cheifet clarified that the display was mirroring that of a Toshiba laptop sitting next to Buffa. Buffa continued, noting this prototype was built for a securities brokerage firm for traders to enter their tickets.

Kildall asked for clarification on Buffa’s claim that NestorWriter used “artificial intelligence,” pointing out this appeared to just be existing optical character recognition technology. Buffa said the AI component came from research done by two Brown University professors, Leon Cooper and Charles Elbaum, who spent the past 15 years trying to build a computer that emulated how the human brain worked in terms of recognizing and classifying patterns. This led to the development of a form of AI called “neural network,” which was the technology used in NestorWriter. Buffa said this same technology could also be used to recognize how mortgage underwriters made loans or decisions on how traders made market decisions.

Key Tronic’s Long Road Away from Keyboards

Of the numerous companies with products featured in this episode, Key Tronic Corporation is probably the most notable, both in terms of its longevity and its historical success in manufacturing input devices for computers. Key Tronic is actually still active as an independent company today nearly 60 years after its founding, although it is no longer in the keyboard business.

The Key Tronic story begins with the company’s founder, Lewis G. Zirkle, who had a six-decade career in manufacturing. Zirkle graduated from The Ohio State University in 1936 with a degree in industrial engineering. He joined General Electric out of college and spent the next 24 years at the company, eventually becoming the manager of a GE plant in Shelbyville, Indiana.

Zirkle left GE in 1961 and moved to Blacksburg, Virginia, where he joined Poly-Scientific Corporation as its executive vice president and general manager. Four years later, Zirkle moved to Providence, Rhode Island to take over as director of manufacturing for Liviton Manufacturing.

In 1966, Zirkle moved yet again, this time to Couer d’Alene, Idaho, where he was named vice president and general manager of Clare-Pendar Co., a manufacturer of illuminated push keys for the data processing and aerospace industries.

After three years at Clare-Pendar, Zirkle decided to strike out on his own, founding Key Tronic Corporation in Spokane, Washington, just across the Idaho-Washington border from Couer d’Alene. The new company formally opened for business in October 1969 with four employees and a 20,000 square-foot manufacturing facility in the Spokane Industrial Park.

Key Tronic’s main business during its early years was producing electronic keyboards for original equipment manufacturers (OEMs). As this was the early 1970s, these were primarily keyboards integrated into data processing and industrial control systems. According to a 1972 profile in the Spokane Spokesman-Review, the first Key Tronic keyboards sold for between $100 and $500 “depending on the size and complexity.” At that time, there were only about a dozen companies in the keyboard industry.

Key Tronic enjoyed early success and grew rapidly in the 1970s. By 1978, Key Tronic had more than 1,000 employees and its operations now filled 170,000 square feet at its original location at the Spokane Industrial Park, as well as two satellite manufacturing plants in the region. The company’s operations had also diversified from focusing solely on OEM keyboards to producing optical character recognition (OCR) systems for corporate customers. One of Lewis Zirkle’s sons, Alfred “Fred” Zirkle, headed up the company’s OCR division before leaving to start his own company in 1981.

It was the emergence of the personal computer, however, that helped pushed Key Tronic to the next level. In the early 1980s, the company started producing OEM keyboards for a number of microcomputers–including the Apple Lisa–as well as after-market boards sold directly to consumers. Indeed, Key Tronic competed against Apple, offering a replacement board for the Apple II, which added a numeric keypad and function keys.

Bolstered by the robust personal computer market, Lewis Zirkle decided to take Key Tronic public in June 1983, selling a roughly 25-percent stake in the company to raise $41.3 million in new capital. The company ended its 1983 fiscal year posting record sales of $80.6 million. The company now manufactured about 1.5 million keyboards per year, accounting for about 25 percent of the worldwide keyboard market. This led Key Tronic to declare itself “the leading independent manufacturer of keyboards in for computers and word processors in the United States,” although some industry analysts noted that IBM likely produced more keyboards overall for its own computers.

Of course, by this point, there was enormous pressure on Key Tronic to start moving at least some of its manufacturing operations outside of the United States. In October 1982, Zirkle announced the company would open three new manufacturing plants in South Korea, Taiwan, and Singapore, causing a loss of 500 jobs in the Spokane area. Zirkle told the press this was necessary to keep Key Tronic competitive and profitable, and in the long run protect more local jobs in Spokane.

Lawsuits, Increased Competition Chipped Away at Key Tronic’s Lead

Despite the successful IPO and continued growth, there were also signs of mounting problems at Key Tronic. While the company enjoyed strong 1983 sales, there was also a $4.8 million write-off to account for failed investments that Zirkle made in other companies. And in March 1983, a Washington civil jury ruled against Key Tronic in an environmental lawsuit brought by five Spokane County property owners. During the 1970s, Key Tronic regularly dumped a cleaning byproduct containing the hazardous chemical 1-1-1 trichloroethane in a local landfill. This chemical was later contaminated the water wells of the five property owners, making the water unsuitable for drinking.

Now to be fair, several other organizations, including the United States Air Force, also dumped hazardous chemicals at the Spokane landfill. Nevertheless, the jury ordered Key Tronic and Spokane County to pay the affected landowners approximately $383,000 in damages. On top of that, Key Tronic agreed to pay an additional $4.2 million to settle hazardous waste disposal claims brought by the federal Environmental Protection Agency (EPA) and the Washington Department of Ecology. Key Tronic subsequently sued the federal government, seeking recovery of $1.2 million from the Air Force for the legal costs that Key Tronic incurred in connection with the EPA settlement. That case eventually made its way to the United States Supreme Court, which ruled against Key Tronic in a 1994 decision.

Despite these setbacks, Key Tronic enjoyed another record year in 1984, reporting $11 million in profits on $131.4 million in sales. The company’s chief financial officer cautioned the press, however, that there had been a slowdown in orders due to the overall downturn in the personal computer market. Increased foreign competition had also led to an “erosion” of keyboard prices.

As the industry slowdown continued into 1985, Key Tronic laid off about 37 percent of its staff and imposed salary and wage freezes on those workers who remained. Twelve of the company’s 30 largest customers went out of business or significantly cut back on their keyboard purchases. Not surprisingly, the balance sheet also went into the red, with Key Tronic reporting two consecutive quarterly losses totaling $2.5 million before sales start to inch up again and Key Tronic posted a quarterly profit of $1.3 million in December 1985.

Heading into 1986, Lewis Zirkle told the Spokesman-Review that he expected Key Tronic to make a comeback. His plan included developing new product lines–such as the KB5153 that we saw in this episode–that could be sold directly at retail to customers. Zirkle believed that this would help to reduce Key Tronic’s dependence on both traditional keyboards and OEM customers.

Zirkle also continued to look for ways to cut Key Tronic’s manufacturing costs. In January 1986, Key Tronic announced it was discussing a possible joint venture with Tokyo-based Minebea Co., Ltd., under which Minebea’s factory in Thailand would serve as a contract manufacturer for Key Tronic keyboards. A few weeks later, the two companies reached a tentative agreement, which included Minebea’s commitment to purchase 30 percent of Key Tronic. This may have been a prelude to an outright sale of Key Tronic. But in August 1986, the parties called the deal off.

A Botched Succession

Soon after the Minebea deal fell apart, Key Tronic announced a new round of layoffs. This included closing one of the company’s three Spokane-area plants and firing a number of senior executives, including the company’s general counsel, Gary Haight. He didn’t go quietly. Haight told the Spokesman-Review the layoffs “may backfire” as the company had now “dismantled its research and development department” and placed “former junior executives” in charge of sales and marketing.

In response to Haight’s comments, Key Tronic senior vice president Charles Reilly said the “reorganization” of the company’s management was necessary “to pull costs down any way we can.”

Meanwhile, Zirkle continued his push for product diversification. In 1988, the company announced its first mouse. There was also a new low-cost membrane keyboard called the “Quicksilver.” But the layoffs continued, with another “reorganization” costing 125 employees their jobs in March 1988, just a few weeks before this Chronicles episode aired. Among those laid off was now-former senior vice president Charles Reilly.

Two months later, in June 1988, Zirkle decided to add Key Tronic president Donald J. Meyers to the list of “reorganized” employees, dismissing him after just two years with the company. One Seattle-area analyst told the Spokesman-Review that he was a “little bit puzzled” by this move, as it created “considerable uncertainty” during a “difficult time in the company’s history.”

Zirkle, the company’s chairman and CEO since its founding, also took back the president’s title following Meyers’ dismissal. But now in his mid-70s, Zirkle knew it was time to start considering a succession plan. It turned out that involved the return of his prodigal son. In July 1989, Fred Zirkle rejoined Key Tronic after an eight-year absence, during which time he’d been founder and president of Alpnet, a successful international translation software company.

Initially appointed as Key Tronic’s executive vice president, Fred Zirkle was now his father’s heir apparent. This prompted dissent from one of Lewis Zirkle’s oldest allies. Shortly after the Key Tronic board approved the younger Zirkle’s re-hiring, company director Robert Simpson abruptly resigned. Simpson had been an outside director on the Key Tronic board since Lewis Zirkle founded the company in 1969.

Simpson told the Spokane Chronicle that Fred Zirkle was the least qualified of the five candidates that the board interviewed for the executive vice president’s position. The other four candidates, all outsiders identified by a recruiting firm, were more experienced. But Fred Zirkle had, in Simpson’s words, “just asked his dad if he could come to work at Key Tronic,” and that was that.

For his part, Lewis Zirkle said he respected Simpson’s position, but he also felt that his son’s previous 12 years working at Key Tronic and experience in international business at Alpnet made him a good fit to take over the company.

The father didn’t wait long to make his son’s succession official. After just four months back at Key Tronic, Fred Zirkle took the president and CEO titles in December 1989 and assumed day-to-day control from his father, who remained chairman. The younger Zirkle said his focus would be on “increasing margins and adding new products.”

To that end, Key Tronic signed a deal in November 1989 to acquire Utah-based Axonix Corporation, a manufacturer of laptop computer peripherals. This was the first step in Fred Zirkle’s plan to make Key Tronic a major player in manufacturing laptops for OEMs. In March 1990, Key Tronic licensed a 386-based laptop computer design from Colorado-based Selsys Corporation. At the Spring COMDEX show that June, Key Tronic showed off a prototype of the machine, which weighed just 5 pounds, ran on AA batteries, and featured a “j-key mouse” that took up the space of a single keyboard key.

The laptop strategy proved to be a costly failure for both the company and the Zirkle family. On August 1, 1991, Fred Zirkle suddenly resigned as president and CEO of Key Tronic, citing “one powerful board member and shareholder who was not satisfied with my performance, and had other priorities.” That powerful board member may have been his father, who reportedly disagreed with his son’s decision to enter the laptop business.

One of the remaining directors, Wendell J. Satre, took over as interim chief executive. Satre, a retired energy company CEO, initially said that he didn’t foresee any “major change” in Fred Zirkle’s plan to manufacture the laptop, which by this point had been in development for two years. But less than a month into the job, on August 29, 1991, Satre decided to pull the plug on the project. Key Tronic wrote off $4.5 million in development costs–more than twice what industry analysts had expected–and Satre proceeded to impose a new round of layoffs and executive reorganization, demoting 8 of the company’s 14 vice presidents.

The Market Helps The Turnaround CEO Who Helps Himself

After reporting total losses of $7.7 million for its 1991 fiscal year, Key Tronic decided it had to double down on its diminishing keyboard business. Unfortunately, that business wasn’t as strong as it had been during the company’s heyday in the early 1980s. As the Spokesman-Review noted, Key Tronic boards than once sold for $50 now commanded $15 or less, and the analysts were skeptical that there was any long-term future for any American keyboard manufacturer.

Nevertheless, the Key Tronic board decided to throw a Hail Mary and hired Stanley Hiller as the company’s new CEO in early 1992. Hiller was something of a living legend in the business community. The son of a wealthy industrialist, Hiller used his family money to establish his first business building gasoline-powered model cars in 1937, when he was just 15. A few years later, he dropped out of college to develop and build a helicopter that he designed. With backing from the United States Navy and another wealthy industrialist, Henry J. Kaiser, Hiller proceeded to start a new company called United Helicopters. Later renamed Hiller Aircraft, Hiller spent the next 25 years building his company into an aerospace giant.

After selling Hiller Aircraft in the mid-1960s, Hiller decided to reinvent himself as a corporate turnaround specialist. He founded The Hiller Group and set about “rescuing” distressed companies. A few years before taking over Key Tronic, Hiller ran York International, a Pennsylvania air conditioner manufacturer, which had fallen on hard times. He reportedly increased that company’s stock price by nearly 500 percent during his two-year tenure.

Hiller’s plan for Key Tronic involved less diversification and more keyboards and keyboard accessories. He shut down most of the company’s internal development and vertical integration, preferring to rely more on outside vendors for parts like printed circuit boards. He also wasted little time shutting down what remained of Key Tronic’s manufacturing base in Spokane. Because the thought of continuing to pay Americans $6 per hour to assemble keyboards was an affront to the stock market Gods, Hiller moved those jobs to a factory in Juarez, Mexico, which Key Tronic acquired from Honeywell Inc.

In the short term, Hiller’s strategy produced the desired results. Among the new products spearheaded by Hiller’s team was a line of “ergonomic” keyboards, which Key Tronic announced at the fall 1993 COMDEX show. This led to what was perhaps Key Tronic’s most famous product: the Microsoft Natural keyboard. Designed for Microsoft’s Windows 95 operating system, the split, angled ergonomic keyboard became the fastest-selling product in Key Tronic’s history and helped propel the company to $4.4 million in profits on $208 million in sales for the 1994 fiscal year.

After a second profitable year in 1995, Hiller decided his work was done. He stepped down as Key Tronic’s CEO in October 1995, turning the reins over to Fred Wenninger, a veteran technology industry executive. Of course, Hiller didn’t walk away empty handed. As part of his deal to take over Key Tronic, he received significant stock options, which he exercised in May 1995, earning a profit of $3.25 million.

Diversification Returns Key Tronic to Stability

Unfortunately, Hiller’s short-term profitability focus didn’t produce lasting results, and the company quickly found itself back in the red following his departure. It was Hiller’s successor, Wenninger, who was then left to shoulder the blame. The board fired Wenninger in June 1997, replacing him with chief operating officer Jack Oehlke, a longtime Honeywell executive who joined the company when it acquired the Juarez facility.

Although Oehlke initially said his plan was to “grow our keyboard business and increase our market share,” the reality was that there wasn’t much room left to grow for a keyboard-only manufacturer. To his credit, Oehlke quickly recognized this and effectively embraced the diversification strategy that Fred Zirkle had tried to implement nearly a decade earlier.

As the 20th century came to a close, the Oehlke-led Key Tronic started aggressively moving away from keyboards and into contract manufacturing for a wide range of products, such as printer components, multimedia touch panels, global-tracking systems, and medical devices. According to a September 1999 report from Dow Jones, Key Tronic’s strategy was now to “focus on products that don’t have complex electronics but that need sophisticated plastic molding and low-cost assembly.”

In August 2000, Oehlke proclaimed that Key Tronic had “turned the corner” and its primary business was now contract design and manufacturing rather than keyboards.

Oehlke remained CEO of Key Tronic until April 2009, when he stepped down due to illness. (He died in December 2011.) Craig Gates, the company’s executive vice president, took over as president and CEO. Gates led the company for the next 15 years, until his retirement this past June, when the company’s chief financial officer, Brett Larsen, took over as president and CEO.

Under Gates and Larsen, Key Tronic actually revived the company’s manufacturing operations in the United States. While the Juarez facility remains Key Tronic’s main production facility, Key Tronic currently has additional manufacturing plants in Mississippi, Texas, Arkansas, and Minnesota. as well as the company’s traditional headquarters in Washington. Altogether, the company today employs about 4,100 people.

Gates told the Spokesman-Review in 2023 that the company started expanding its domestic production capacity about 5 years earlier due to concerns over rising Chinese labor costs and the long lead times required for overseas contract manufacturing. This proved to be an especially prescient move when the COVID-19 pandemic largely ground global supply chains to a halt. Combined with the deteriorating political relationship between the governments of the United States and China, Key Tronic reported a ten-field increase in its contract work, ranging from face masks and high-end respirators to wireless security devices and electric vehicle charging equipment.

In its most recent filings with the Securities and Exchange Commission, Key Tronic reported $2.78 million in losses on $566.9 million in sales for the 2024 fiscal year. This represented a 6.3 percent decrease in sales from 2023, which management attributed to “softer demand from Mexico-based programs” and a “cybersecurity incident” that temporarily shut down production during the fourth quarter.

Notes from the Random Access File

- This episode is available at the Internet Archive and was likely first broadcast during the week of April 24, 1988. The recording on the Archive is a rerun from sometime in late 1989.

- Gary Kildall’s reference during the introduction to a kiosk that allowed you to buy shoes using a touchscreen interface was a real thing. In 1987, Florsheim Shoes debuted the kiosks, which it called “electronic sales assistants,” with about 375 units operating around the country by August 1988. California-based ByVideo, a company started by Atari co-founder Nolan Bushnell, manufactured the kiosks for Florsheim, which cost between $8,000 and $10,000 each.

- Tony Mendicino spent 28 years with the United States Postal Service, rising to chief operating officer for the western states before retiring in 2003. An industrial engineer by training, Mendicino has worked as a hospitality and wine industry consultant since leaving the Postal Service.

- In 1989, Key Tronic’s Dan Mertens jumped to one of the other companies featured in this episode, joining Tim Barry at MicroSpeed as vice president of marketing. Barry founded MicroSpeed in October 1985. The company continued manufacturing trackballs into the mid-1990s, and it seems operations ceased sometime around 2002.

- Victor Kley died in November 2023 at the age of 77. Born in Washington, DC, in 1946, Kley started a number of tech companies, including General Nanotechnology, Rave LLC, Attoscopy, and Kley Associates Design Group, which he later renamed Lightgate. According to an obituary in Berkleyside, Kley even developed a miniature touchscreen in the late 1970s, which he unsuccessfully tried to sell to Apple co-founders Steve Jobs and Steve Wozniak. Kley was also a noted anti-war and environmental activist and helped organize the first Earth Day celebration in April 1970.

- Lightgate dissolved in February 1988, just a few weeks before this episode first aired. Victor Kley subsequently sold the rights to Felix to Wyoming-based Altra Corporation, which continued marketing the Macintosh-only input device into the early 1990s, at one point introducing a Windows-compatible version.

- Despite my headline snark and Gary Kildall’s skepticism, Nestor actually was involved in artificial intelligence research. The two Brown professors that Michael Buffa referenced, Leon Cooper and Charles Elbaum, were actually Nestor’s co-founders. Cooper, who died this past October at the age of 94, shared the 1972 Nobel Prize in Physics with two of his colleagues “for their jointly developed theory of superconductivity, usually called the BCS-theory.” (Don’t ask me what that means.) Cooper’s interests then turned to neuroscience, which led him to start Nestor with his colleague Elbaum, in an attempt to develop commercial application sfor so-called neural networks. While NestorWriter, which sold for $1,595 at launch, was never meant to be a bestseller, Nestor continued to market and license the handwriting recognition software well into the early 1990s. Nestor itself became more well known for a subsidiary, Nestor Traffic Systems Inc., which developed and sold speeding cameras to municipal governments and police departments. In September 2009, Verra Mobility acquired Nestor Traffic Systems, and the Nestor parent company closed shortly thereafter.

- An electrical engineer by training, Michael Buffa held management positions with General Electric and Honeywell in the 1970s. In 1981, he joined Florida-based Computer Products Inc., to start a factory automation division. In 1984, Buffa moved to Michigan to start an artificial intelligence unit for Machine Vision International Inc. After that company went public–and made Buffa a milliionaire–he took over as president and chief operating officer of Providence, Rhode Island-based Nestor, in 1986. Buffa later told the Orlando Sentinel that his job at Nestor “was to clean up a mess” and that he “would never go into that situation again.” Buffa only remained at Nestor for three years, leaving in 1989 and moving to Europe for several years. Buffa ultimately returned to the United States, and Florida, and in 1998 became chairman and CEO of Milcom Technologies, a company that created startups to develop civilian applications for military technologies. Buffa retired from Milcom in 2005.

- Founded in 1968, Pennsylvania-based Numonics Corporation first became known in the 1970s for its digitizer technology. Later, the company was a major manufacturer of computer-aided design systems. In the 1990s, Numonics expanded its product lines to include X-ray imaging and interactive whiteboards. Numonics went out of business sometime around 2019.

- The Lite-Pen Company was founded in Los Angeles in October 1983 and, as best I can tell, ceased operations around 1990. In its review of the L-PC Lite-Pen featured in this episode, PC Magazine praised the device’s cord as a “stroke of genius compared with other light pen cords,” as it contained a “straight section” that helped reduce the strain of holding the pen for extended periods. Unfortunately, there wasn’t much software usable with the Lite-Pen, and if you wanted to take advantage of a higher-resolution adapter board, you needed to write your own software drivers.

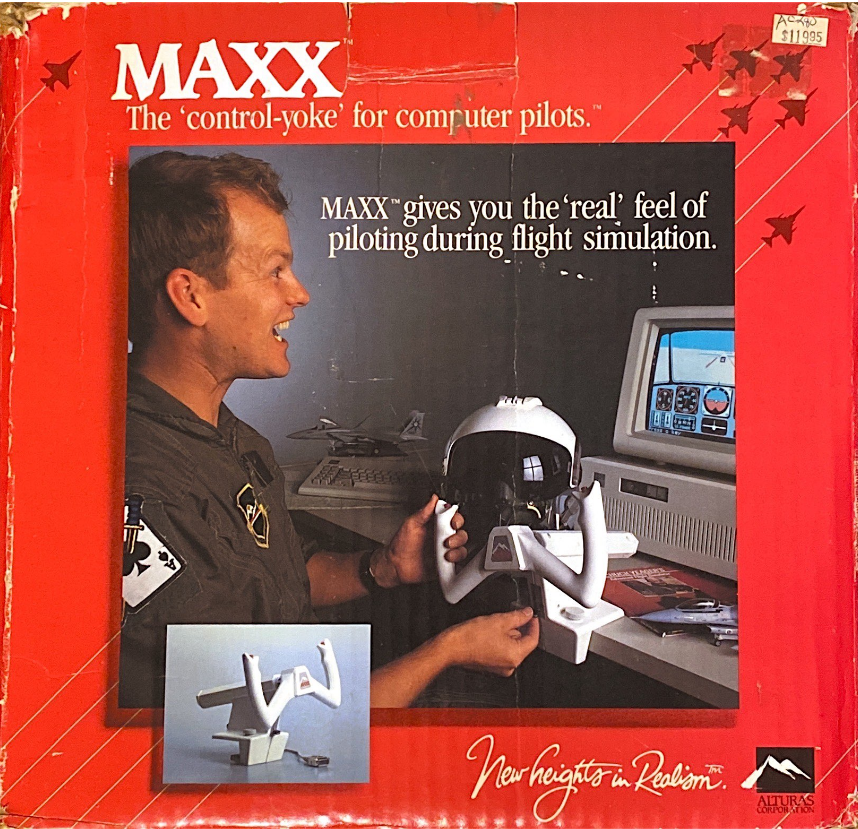

- In his cold open, Stewart Cheifet appeared at a computer store where he showed off the Maxx control yoke, a vertical joystick used with flight simulator games (see below). Alturas Corporation, a short-lived company based in Cour d’Alene, Idaho, manufactured the Maxx between 1987 and 1989. Another Idaho-based company, Maxximum Co, then assumed the rights to the Maxx and continued to provide service through the mid-1990s. Incidentally, Cour d’Alene is just across the Idaho-Washington border from Spokane. That suggests there could be some connection between Alturas/Maxximum and Key Tronic, although my research turned up no direct link.