Computer Chronicles Revisited 12 — The Xerox Color Laser Printer

Today’s episode contains what Stewart Cheifet would later describe as one of the classic “near disasters” involving a product demonstration on The Computer Chronicles. The subject was the first Xerox Color Laser Printer, which was actually a prototype not yet available for sale when this Chronicles episode taped in October 1983. Cheifet recounted the event to Tonya Hall of ZDNet in a November 2020 interview:

We introduced the very first color laser printer on the show by Xerox. I figured it’d be a printer–it was the size of two Volkswagens! We had to take the doors off the studio to get this thing inside. And it took three engineers three hours to get this thing hooked up. And I said, ‘Can we test it now?’ ‘Yeah, let’s test it.’ We went to the print button, hit the print button, and smoke came out of this printer. No output–smoke. I said, ‘Look, we’ve got to get this thing to work, guys.’ Finally, another hour later, they pressed the button and I saw the most gorgeous color output I’ve ever seen in my life from a computer.

Smoking printers notwithstanding, this episode was essentially a product demonstration showcase for Xerox and its Diablo Systems division, the latter of which was marketing commercial printers in late 1983 using a variety of technologies.

Herbert Lechner was back in the co-host’s chair this week. Cheifet opened by asking Lechner why it seemed that printer technology had lagged behind computer technology in general. Cheifet noted the printer was the slowest component of the system, the prices had not come down that much, and it was often the first part of a system to break. Why was that? Lechner said it came down to the fact that the mechanical components of printers had not seen the types of breakthroughs that we’d seen in the electronic areas. Manufacturers were well aware of this problem and were trying to become less dependent on the purely mechanical functioning of printers by developing more electronic-controlled components.

Cheifet then narrated our B-roll for the week, which briefly reviewed printer technology. He started with the census-taking machine invented by Herman Hollerith in 1890, which only had one task: to collect and tabulate large numbers more efficiently than humans. Like other early mechanical computers, the Hollerith machine only had limited memory and the printout of the stored information was limited to the final computation.

As computers became less mechanical and more electronic, Cheifet said, information retrieval also became more flexible. Once data could be magnetically encoded onto a reel of tape, that data could now be changed or erased instantly and the recorded medium used over again. This made printed information–i.e., hardcopy–unnecessary as long as the data was used only within the functions of the machine. Information only became more perishable when video display terminals became standard computer components.

But while today’s computers may have reduced the need to stockpile written information, Cheifet noted that a quick look at the typical modern office revealed that one of the most common peripheral devices was now a printer. Popular impact printers like the daisy wheel still operated much like a typewriter, albeit with fewer moving parts and greater speed. And while advances in printer technology to date had not matched the progress on the electronic side, the trend away from mechanical complexity had brought paper-and-ink printing to a new level of sophistication. The focus was now on developing non-impact printers using heat, electricity, and photo-type setting–and even lasers that burned characters into the paper.

“How Fast Are the Squirts?”

Cheifet and Lechner introduced two guests from Diablo Systems, Steve Rea and Paul Shapiro. Lechner asked for an overview of the types of printers currently available for computer users. Shapiro explained there were two basic categories of printer: impact and non-impact. And within each of those categories there were different technologies available. For example, dot matrix printers were a type of impact technology, while inkjet printers were considered a non-impact technology. Within these groups, Shapiro noted there were also various cost-performance ranges, in addition to the differing qualities of the print, which were measured in spot density.

Cheifet asked how a user would know what printer was right for him? Rea said impact printing was good if you wanted to produce a hard copy that was good enough for letters and mailers. But if you needed high-speed output you might want to go with thermal printing technology, which involved a thermal transfer to plain paper. And if you needed color output, you had to go with an inkjet.

Cheifet followed up, asking how a consumer would chose between two printers using similar technologies, such as dot matrix and daisy wheel. Shapiro said again, the answer came down to the quality of output you were looking for as well as the speed. If you needed letter-quality, fully formed characters, he would gravitate towards the daisy wheel. But if you only needed “draft” quality and wanted to focus on speed, dot matrix might be the way to go.

Lechner asked where thermal printers fit in. Rea said Diablo’s thermal printer was very high speed and could output about 6 pages per minute. In contrast, a daisy wheel only produced 1 or 2 pages per minute. The inkjet was even slower because it worked with color.

Rea then conducted an EXTREMELY NOISY demo of Diablo’s daisy wheel printer. He note this technology had been on the market for many years, having been introduced by Diablo in the early 1970s. He explained the printer relied on a character wheel with 192 fully formed characters. This allowed for printing scientific notation and other specific applications. He noted that with a single print wheel the printer could print 33 different western European languages. Shapiro added the current trend with daisy wheel technology was to add even more characters per print wheel. New accessories were also popular, such as the double-bin feeder used on the demo model. This made it possible to increase the daisy wheel printer’s output over time. In response to a follow up question, Rea said the running speed of the daisy wheel was about 40 characters per second.

The group then moved to a thermal printer. Rea noted this was a much quieter unit compared to the daisy wheel. It also cost more because you were getting extra speed from the thermal printer. Shapiro added the thermal unit produced about 6 pages per minute–as opposed to roughly 2 from the daisy wheel–yet it was only twice the price. In terms of spots-per-inch, the daisy wheel was also more dense (450 SPI) than the thermal (200 SPI).

Lechner then asked about the inkjet printer–specifically whether this was where the market was moving. Shapiro said as graphics became a more important part of personal computer use, the market was gravitating towards graphics and color, especially with machines like the Apple Lisa that had bitmap graphics–i.e., the ability to control each and every bit on the picture tube and every bit on a page.

Lechner asked about the interfaces used to connect printers to computers. How would a customer know they were buying something where the plug would fit? Rea said Diablo relied on all-purposes interfaces. he agreed the typical PC user wanted “plug and play.” As such, Diablo printers could run using a standard parallel or serial connection.

Rea then demonstrated the final of the three Diablo printers, the Series C color inkjet. He explained the Series C utilized “drop on demand” technology, which enabled the printer to squirt a drop of ink per nozzle onto the paper. Lechner asked, “How fast were the squirts?” Rea said it amounted to 20 characters per second for text. The printer’s four ink colors could also be mixed to produce a total of 7 different colors (and 8 if you included white). He added the inkjet was very quiet and could be placed next to an individual workstation. Cheifet asked about the cost. Shapiro said the Series C was slightly less expensive than a fully formed character printer and about one-fifth the cost of a thermal unit.

Cheifet ended the segment by asking about the limits to thermal printing, such as the need for special paper and the inability to use fan-folded paper. Shapiro said that was only partly correct. Diablo relied on thermal transfer rather than “direct” thermal transfer. Thermal transfer allowed for the use of traditional bond paper. As for fan folding, it wasn’t necessary as you could use pre-cut sheets.

“I Will Spray Some Freon”

The final segment focused on the previously mentioned Xerox Color Laser Printer. The segment began on the set with Lechner talking with Dr. John Urbach, the manager of optical science for Xerox PARC. Urbach provided a broad overview of how laser printing technology worked. He noted it was similar to that of a [CRT] television set. Only in this case a finely focused beam of light from a laser was scanned across a line. It was turned on and off at a very high rate using a modulator, and this painted out regions of illumination (or lack thereof) along the scan line. This scan line could then be repeated over and over again, and some kind of light-sensitive recording medium was then moved along underneath the scan line to generate a 2D image. This was similar to an inkjet, but the laser printer was faster and produced a higher resolution.

Lechner asked just how fast the laser printer was. Urbach said in terms of pages, it varied between 3 and 10 per minute. Lechner then asked for more detail about the “flexibility” offered by a laser printer. Urbach said that since you could paint out every possible resolution on the page just like a television, you had the ability to create a completely arbitrary map of any type of image information that a computer could generate. That said, Urbach added that most computers were not presently flexible enough to take full advantage of this capability. But if a computer could generate an image, then within some very broad limits the laser printer could print it.

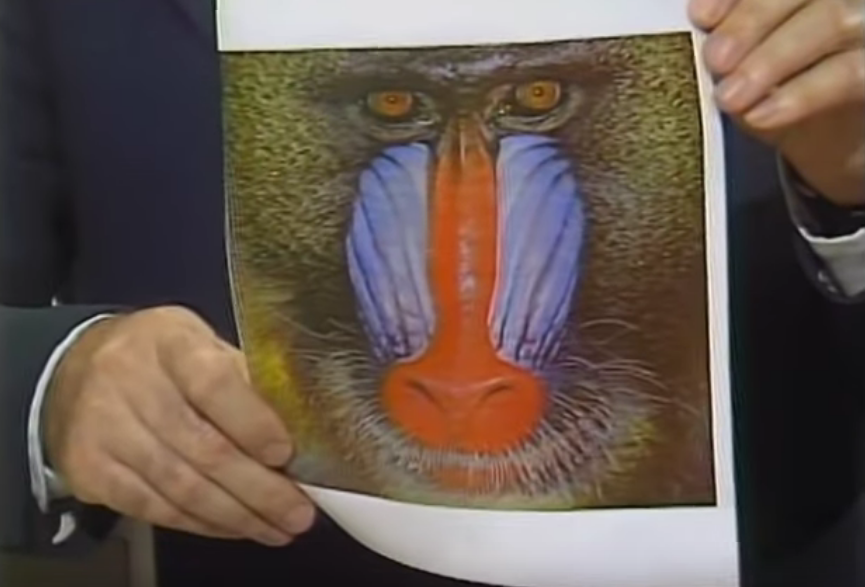

The focus then shifted to Stewart Cheifet and Xerox research engineer Douglas N. Curry, who began the demo of the actual color laser printer–which Urbach emphasized was still an experimental device and not a standard product. Curry briefly explained that he would print a color image of a baboon. To do this, you had to superimpose three separate images of magenta, yellow, and cyan. The three layers were first printed separately before the final image.

There was then a very awkward cut, which I’m guessing is where they had the issue with the smoke. Cheifet was now seen with another Xerox employee, Tibor Fisli, who supervised the final printing of the baboon image (which is seen in the thumbnail for this blog post). Fisli also briefly reviewed the laser printing process as previously described by Urbach.

After reviewing what Cheifet called the “impressive” final printout of the baboon, Fisli showed a duplicate of the actual laser printing assembly from the Xerox Color Laser Printer. Cheifet asked if it was possible to see the actual laser beam. Fisli, showing a complete disregard for the Ozone, said, “I will spray some Freon,” which then made the path of the laser visible.

Back on the main set, Lechner asked Urbach about the future. Would we see more laser printers? Would they come down in price? And would it displace the other printer technologies discussed today? Urbach said the answer to all of those questions was “yes”. There would be more laser printers and they would come down in price. Early laser printers were fast but expensive, as they cost hundreds of thousands of dollars. The price had now started to come down rapidly thanks to the use of junction diode lasers, which would replace the larger helium neon laser used in the earlier demonstration unit.

Diablo’s Short Run as Daisy Wheel Queen

I don’t have much to say about the people or products in today’s episode. Tibor Fisli apparently passed away in 2001. The only other person I came across information for was Steve Rea, who bounced around a number of well-known technologies but seems to have spent the most time at Apple, with stints in Cupertino from 1988 to 1997 and again from 2009 until January 2021.

Diablo Systems was founded in 1969 and manufactured early disk drive systems and daisy wheel printers. Xerox acquired Diablo in 1972 in an all-stock deal valued at around $28.6 million, according to The New York Times. As a Xerox division, Diablo’s best known product was the Diablo 630, the daisy wheel printer that was likely used in the Chronicles demo.

Xerox, of course, is very much still in business and continues to manufacture laser printers.

Notes from the Random Access File

- This episode is available at the Internet Archive, where it is dated May 14, 1984. The actual recording date was October 10, 1983.

- The Hollerith machine mentioned by Stewart Cheifet during the B-roll was apparently used by the Census Bureau well into the 1950s, when it was replaced by electronic computers.

- Although the color unit seen in this episode was still a prototype, Xerox did bring the first black-and-white laser printer to the market back in 1977, the Xerox 9700.

- According to an article by Erik Arctander and John Free for the February 1984 issue of Popular Science, the Diablo Series C inkjet was actually made by Sharp and retailed for $1,200, which was considered a “surprisingly low cost” at the time.

- In comparison, the Diablo thermal-transfer printer would set you back about $5,000, according to the April 4, 1983, issue of ComputerWorld.

- If you want to learn more about the daisy wheel technology, there’s a fun video originally produced by Xerox and later posted to YouTube by the Computer History Museum that demonstrates the process of making the actual daisy wheels.

- The casual spraying of Freon seen in this episode would effectively be banned by international treaty a few years later. The Montreal Protocol on Substances that Deplete the Ozone Layer was signed in 1987 by the United States and 45 other countries. It phased out the use of chlorofluorocarbons (CFCs), which included Freon.